Bench drill rig

Description

Drill jumbo - precise, efficient, automated

Thanks to computer-controlled drilling depth monitoring, the drill rig ensures particularly precise and effective blasting results - with minimal labour requirements. The integrated electronic parallel guidance reduces the number of drill holes required, saves on explosives and significantly increases blasting efficiency.

Easy-to-create drilling programmes guarantee high repeat accuracy and make day-to-day work easier. The high degree of automation not only makes drilling operations much easier, but also opens up a wider range of applications for the operator.

- Rotary drilling / Hammer rotary drilling

- Electric / Diesel

- Radio remote control

- Semi-automatic

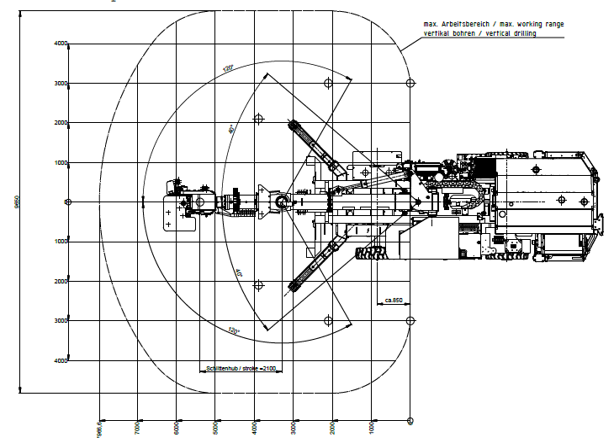

- Unrivalled working range

General Technical Data

| Height above machine assemblies | mm | 1700 - 2400 |

| Length over all in transport position | mm | 11900 |

| Overall width in transport position (driver's platform left longitudinal) | mm | 2855 |

| Curve radius, outside / inside | mm | < 8.260 / < 3.570 |

| Max. driving speed on the level | km/h | 18 |

| Max. driving speed with max. incline of 28% | km/h | approx. 4 |

| Climbing ability | % | 30 / 15 |

| Unladen weight | kg | 18.000 |

Technical Data Chassis / Drive System

| Drive motor | ||

| Fuel type | - | diesel |

| Manufacturer | - | Deutz / CAT |

| Type | - | TCD 3.6 / C4.4 |

| Exhaust stage | - | Stage 5 |

| Powershift transmission | ||

| Manufacturer | - | Dana - Spicer |

| Front axle | ||

| Manufacturer | - | Kessler |

| type | - | Drum or disc brake |

Drilling Arm

| Useful bore length max. | mm | 60000 |

| Performance data of the drill drive | ||

| Drill motor speed / rotation speed of the drill rod | min-1 | 0-1200 |

| Direction of rotation | right / left | |

| Drill hole diameter | mm | 34 - 60 |

| Drive drilling type | Percussive rotary drilling / rotary drilling | |

| Drill drive type | Hydraulic |