Blasthole Drill Rig

Description

Blasthole drilling rigs - precision and efficiency for decades

Our blasthole drilling rigs are equipped with a fully automatic, coordinate-controlled drilling system that has been successfully in use for over 30 years and is continuously being developed further. Drilling depths of up to 7 metres can be achieved effortlessly.

Thanks to the high degree of automation, the rig guarantees maximum precision when drilling and thus ensures optimum blasting results. This not only has an impact on safety, but also reduces the use of explosives - and therefore also the costs.

Our blasthole drilling rigs fulfil the highest technical standards in mechanics, hydraulics and control and therefore stand for maximum reliability and efficiency in daily use.

- Rotary drilling / rotary hammer drilling

- Radio remote control

- Semi-automatic

- Drill pass

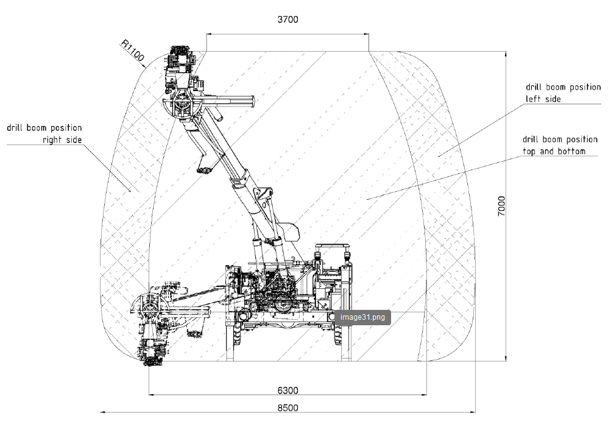

- Unrivalled working range

- Low profile available

General Technical Data

| Height above machine assemblies | mm | 1700 - 2400 |

| Length over all in transport position | mm | 12000 |

| Overall width in transport position (driver's platform left longitudinal) | mm | 2855 |

| Curve radius, outside / inside | mm | < 8.260 / < 3.570 |

| Max. driving speed on the level | km/h | approx. 18 |

| Max. driving speed with max. incline of 28% | km/h | approx. 4 |

| Climbing ability | % | 30 |

| Unladen weight | kg | 17.800 |

Technical Data Chassis / Drive System

| Drive motor | ||

| Fuel type | - | diesel |

| Manufacturer | - | Deutz / CAT |

| Type | - | TCD 3.6 / C4.4 |

| Exhaust stage | - | Stage 5 |

| Powershift transmission | ||

| Manufacturer | - | Dana - Spicer |

| Front axle | ||

| Manufacturer | - | Kessler |

| type | - | Drum or disc brake |

Drill Arm

| Useful bore length max. | mm | 7300 |

| Performance data of the drill drive | ||

| Drill motor speed / rotation speed of the drill rod | min-1 | 0-1500 |

| Direction of rotation | right / left | |

| Drill hole diameter | mm | 34 - 60 |

| Drive drilling type | Percussive rotary drilling / rotary drilling | |

| Drill drive type | Hydraulic / Hydraulic | |

| Drilling mode | Electric / Diesel |