DSB 1/4

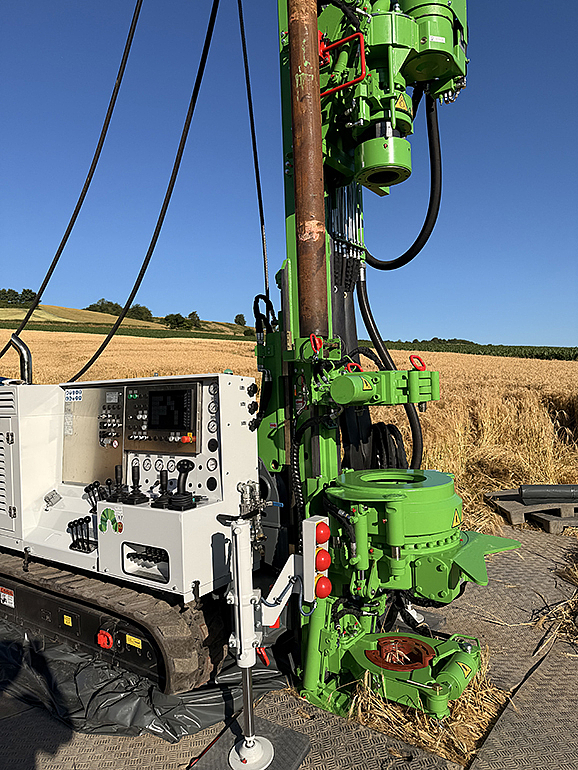

Compact, flexible and powerful - Nordmeyer. Made in Germany.

Our compact drill rig stands for maximum efficiency in confined spaces and offers the usual Nordmeyer quality - robust, durable and practice-orientated. With a total weight of only 8.8 tonnes and a frame width of just 1,700 mm, this machine is ideal for confined construction site conditions, for example in inner-city areas or on sites that are difficult to access.

The machine is powered by a water-cooled 4-cylinder turbo diesel engine from Deutz® with 85 kW (116 hp). If required, the engine output can be increased to 105 kW via a software update - ideal when additional reserves are required. The engine fulfils the requirements of emissions stage V and operates with particularly low emissions thanks to AdBlue® technology. With a sound pressure level of just 77 dB(A) at the operator's platform, the machine enables quiet and focussed work - even during longer operations.

The integrated impact device is designed for an impact weight of up to 800 kg at 60 blows per minute - ideal for well drilling, exploratory drilling and cased dry drilling. The diesel tank is integrated into the frame to save space, which further emphasises the compact design.

A particular highlight is the high level of configurability: the machine can be flexibly adapted to different drilling methods - from classic flush drilling to cased percussion drilling and geotechnical applications. This versatility makes it a reliable all-rounder for drilling operations with changing requirements.

Nordmeyer delivers technology that fits - on every construction site.

Technical specifications

Device Carrier

Crawler undercarriage

Chassis

with solid rubber tracks

Engine Power

85 kW

Emission Standard

EU Stage 5

Tractive Force

49 kN

Feed Length

4,4 m

Drilling Head Torque

10.000 Nm

Rotation Speed

350 U/min

Hollow Shaft / Inner Diameter

65 mm

Machine Width

1.700 mm

Total Weight

7.800 kg

Field of application

Subsoil investigation

Well construction

Sampling

Core drillings

Geothermal energy

Possible drilling methods

Direct flush drilling

Dry drilling

cable percussion drilling

Auger drilling

Percussion coring (Düsterloh hammer)

Core drilling

Hollow stem auger drilling

Options Equipment features

Mast shift

Cable winch 1,900 kg

Cable winch 5,000 kg

rotary casing table Ø 324 mm

eccentric screw pump

Piston pump

Centrifugal pump

Hydraulic clamping head

clamping device

Auxiliary compressor

Hydraulic hammer

High pressure cleaner

cable depth measurement

Flow meter measuring device for water

Drill Pipe Break-Out System

Power generator

Device monitoring and fleet management (SMAGLink)

External hydraulic connections

Tractive force

49 kN

Chassis

with solid rubber tracks

We are here for you

Do you have any questions?

Quick results

Product finder

Simply enter your individual criteria and directly find your device for a smooth process.